Manufacturing Unit

Industry-leading Granite Manufacturing Practices

The increasing use of granite in architectural applications has created a strong demand for precisely-cut, exquisitely polished, and safely transported granite products. This asks for a superior level of granite processing capabilities. Be it a residential construction project or a commercial one, high-quality granite products always pave the way for aesthetically pleasing and sturdier structures.

Regatta Granites India stands as a beacon of excellence in the granite manufacturing and exports sector globally, renowned for its commitment to quality, precision, and innovation. With nearly three decades of industry experience, Regatta has established itself as a trusted name, delivering superior granite products to clients worldwide.

Being in the industry for several years, we are well aware of the evolving dynamics of the construction sector and utilize state-of-the-art machinery and proven practices to manufacture avant-garde granite products for our buyers. We emerge as the first and foremost choice among granite importers, architects, wholesalers, and construction companies for their need of both standard and custom granite products.

Redefining granite manufacturing excellence

A glimpse into our granite manufacturing unit

Comprehensive granite processing

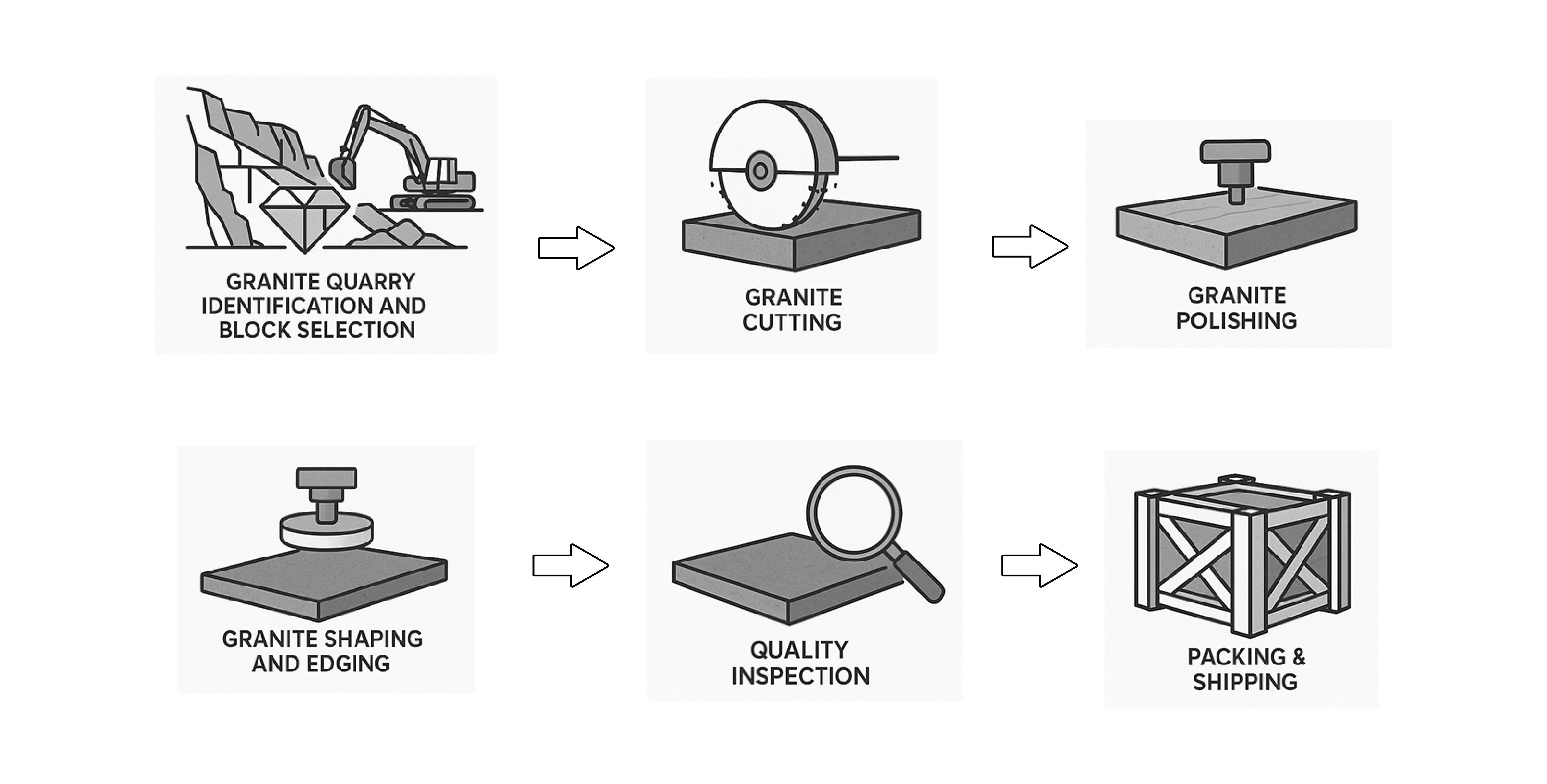

Being a natural stone, granite is extracted from the quarries located in different parts of the country. Below is a step-by-step explanation of granite manufacturing so as to help you understand the complexity involved at every stage. At Regatta Granites India, we pay closer attention to every process to negate any scope of error during granite processing.

Granite Manufacturing Process

1. Granite quarry identification and block selection

Everything starts with granite mining and quarrying, in which granite blocks are cut and extracted from the chosen quarry using various methods. This step is extremely crucial as it forms the base for further processes and final product quality.

When it comes to ensuring continuous supply of high-quality granite, it becomes necessary to choose a reputed and reliable supplier of granite blocks.

A number of factors are considered while selecting a granite blocks supplier. A study of all relevant mines is conducted, which includes the inspection of blocks for color consistency, surface integrity, mineral veining, and possible defects. Experts suggest choosing granite blocks that are visually appealing and physically solid.

The use of modern machines enables quarry owners to extract the finest quality blocks without causing harm to the sensitive environment.

Once the identification of the granite quarry is done and the blocks are extracted, they are checked for any underlying defects. Our professional and experienced granite inspectors check them thoroughly, including their color uniformity, size, mineral veining, and surface finish. The objective is to define the overall quality of the granite block.

2. Granite Cutting

Granite cutting is a crucial step in the overall granite manufacturing process. It encompasses the primary shaping of rough granite blocks with the use of specialized cutting machines like a diamond wire saw or diamond blade saw.

For effective granite cutting, granite manufacturers in India either use a circular diamond blade or a diamond wire saw. Industrial-grade diamonds used in these tools are exceptionally hard and can cut even the hardest granite block easily.

3. Granite Polishing

Once the granite is precisely cut, its surface is treated to attain the desired look and texture. There can be a number of finishes applied to the granite surface such as polished, honed, bush hammered, lepatora, brushed, and others

Epoxy resin is sometimes applied to the surface of granite slabs during the finishing process; this process is called granite resining. For granite varieties that naturally have fissures, cracks, or voids, this stage is very crucial. By filling in these imperfections, the epoxy strengthens and lengthens the stone’s lifespan. Furthermore, applying epoxy makes it easier to create a flawless, flat surface prior to the last polishing step. To guarantee the greatest results, we only use the best and most dependable epoxy.

Granite slabs are given a glossy, reflecting appearance by polishing, the last step in the production process. By bringing out its unique colors and patterns, the granite polishing process accentuates the stone’s inherent beauty.

4. Granite Shaping and Edging

The granite slabs may undergo additional shaping and edging processes for various uses in order to attain exact proportions and designs. Slabs may be cut into smaller pieces, shaped into counters or tiles, and edged for a flawless finish as part of the process.

5. Quality Inspection

Strict quality control procedures are used during the cutting and processing phases to guarantee that the granite satisfies the necessary requirements for strength, durability, and aesthetic appeal.

6. Packing & Shipping

For safe transportation, granite must be packaged and loaded into granite containers.

Following processing and successful quality control inspections, the granite items are carefully packed and ready to be shipped to their final location, which could be a distributor, showroom, or building site.

Advanced machinery for unmatched precision

The integration of fully automated machines in Regatta’s manufacturing units facilitates:

- High-Volume Production: Meeting large-scale demands efficiently.

- Consistent Quality: Uniformity across all products.

- Custom Finishes: Offering a variety of textures and appearances.

- Reduced Waste: Optimizing resource utilization

Such technological advancements position Regatta at the forefront of the granite manufacturing.

Rigorous quality control

Quality is paramount at Regatta. Each product undergoes thorough inspections to detect and rectify imperfections, such as fissures, chipped edges, or color inconsistencies. This dedication to excellence ensures that clients receive flawless granite products that exceed expectations.

Secure packaging & timely delivery

At Regatta Granites India, we are well aware of the importance of safe and secure transportation and employ robust packaging methods:

- Sturdy wooden crates: Protecting products during transit.

- Plastic sheets between slabs: Preventing scratches and damage.

- Fumigation: Ensuring compliance with international shipping standards.

Coupled with a reliable logistics network, Regatta guarantees the timely delivery of consignments, maintaining the integrity of each product upon arrival.

Global Reach with Local Expertise

Regatta’s extensive portfolio includes a diverse range of Indian granite varieties, catering to both residential and commercial projects. Their ability to provide customized solutions, combined with competitive pricing and exceptional service, has earned them a loyal clientele across the globe.