India is one of the best granite exporters in the global market with an exceptional variety of natural granite stones, although it is a commercial stone it also promotes health and comfort which makes it a very common choice. Following is an elaborate account of how leading Indian granite manufacturers and exporters meet with global standards and customer expectations of quality.

Quality Control from the Beginning: Selecting the Granite Quarry

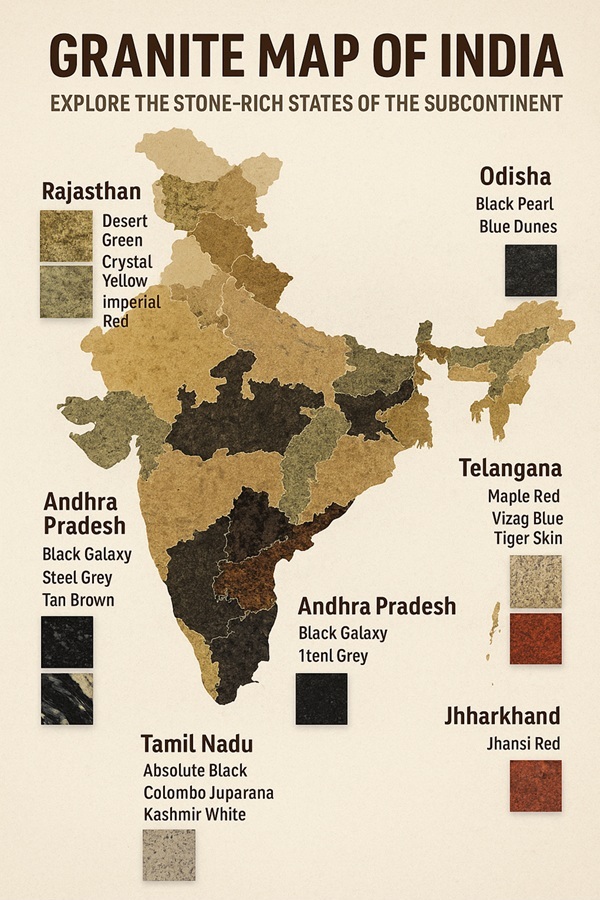

The way to quality assurance in granite manufacturing and exports begins right at the source—the quarry. There are numerous granite quarries in states like Andhra Pradesh, Tamil Nadu, Rajasthan, and Karnataka that are known for their richness and geological assortment.

Major Granite Regions in India and Their Traits

State | Popular Granite Types | Distinctive Qualities |

Karnataka | Black Galaxy, Hassan Green | Superb hardness, uniform texture |

Andhra Pradesh | Tan Brown, Vizag Blue | Sharp color contrast, heat-resistance |

Tamil Nadu | Paradiso, Colombo Juparana | Exotic veining, export-friendly availability |

Rajasthan | Desert Brown, Crystal Yellow | Earthy color tones, large block sizes |

Processing Using Advanced Machinery

After the granite is taken from the quarry, the granite processing is done using advanced machinery to preserve natural diversity and level up the durability.

State | Popular Granite Types | Distinctive Qualities |

Karnataka | Black Galaxy, Hassan Green | Superb hardness, uniform texture |

Andhra Pradesh | Tan Brown, Vizag Blue | Sharp color contrast, heat-resistance |

Tamil Nadu | Paradiso, Colombo Juparana | Exotic veining, export-friendly availability |

Rajasthan | Desert Brown, Crystal Yellow | Earthy color tones, large block sizes |

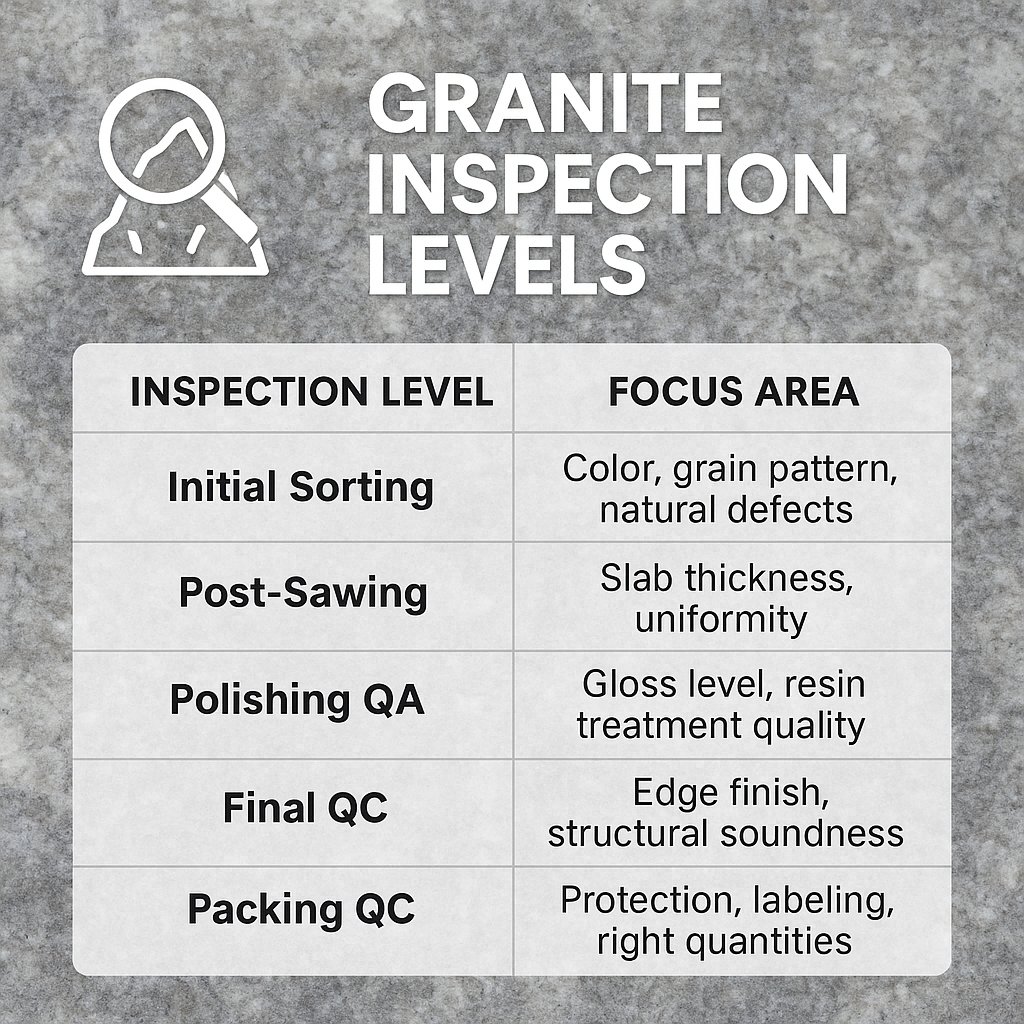

3. Multi-Stage Quality Control Mechanism

Almost every leading Indian granite exporter follows a multi-stage quality control mechanism to find ongoing defects early and guarantee reliable export-grade results.

Granite Inspection Checklist

Inspection Level | Focus Area | Inspection Type |

Initial Sorting | Color, grain pattern, natural defects | Visual, manual sorting |

Post-Sawing | Slab thickness, uniformity | Measurement tools, gauges |

Polishing QA | Gloss level, resin treatment quality | Gloss meter, visual check |

Final QC | Edge finish, structural soundness | Drop test, water test |

Packing QC | Protection, labeling, right quantities | Final checklist, photo record |

Customization for Global Client Needs

Indian granite manufacturers & exporters are able to satisfy the diverse needs of the construction world from the residential, commercial to building projects.

Available Customization Options

Customization Type | Available Options |

Thickness | 12mm, 15mm, 18mm, 20mm, 30mm |

Surface Finish | Polished, Honed, Leather, Flamed, Bush-hammered |

Cut Sizes | Tiles, Full slabs, Countertops |

Edge Profiles | Bevelled, Bullnose, Ogee |

Pre-fabrication | Sink cut-outs, drain grooves, edge polishing |

Export-Ready Packaging & Logistics

And when you’re a global client, you require those kinds of granite slabs and tiles to arrive at your site in perfect safety and condition, even after having traverse thousands of miles. Prominent Indian export and packing protocol:

Component | Purpose |

Wooden Crates (ISPM-15) | Protect slabs during sea transit |

Foam Sheets / Plastic Wrap | Scratch resistance and moisture protection |

Thermocol Corners | Edge protection during transit |

Steel Strapping | Crate strengthening |

Container Stuffing Plan | Space enhancement and transit prevention |

The Verdict

From rough blocks at the quarry to finished slabs installed in wealthy homes or high-rise office buildings overseas, Indian granite follows a complex, multiple-step path to market. And top producers and exporters utilize technology, skills, certifications and customer-centric approaches to provide stone that meets – and often exceeds – global standards.