Blog

Popular ASTM International Standards for Granite Testing

Popularly called ASTM International, “American Society for Testing and Materials”, ASTM refers to a creator of internationally controlled accord standards. ASTM standards are released by committees of significant industry experts who meet and discuss routinely in an open and transparent process to prepare quality standards, testing methodologies, qualifications, guides, and practices. The use of ASTM quality standards is prevalent in the natural stone industry.

Being a famous construction stone, granite remains in huge demand worldwide. With more than 300 varieties available to choose from, today natural stone buyers have the option to choose from a wide range of stone products in different shapes, sizes, and finishes. This means it has become quite easier to get a stone for any specific application.

What do ASTM values mean?

The American Society for Testing and Materials International (ASTM) is a non-profit organization renowned throughout the world for testing and publishing material standards. It is devoted to the development of voluntary consensus standards for materials (including natural stone), products, systems, and services. The stone industry relies on ASTM standards because they offer a realistic and consistent set of standards and testing processes for stone goods. The stone business and those who work with it would be in disarray without ASTM standards. Moreover, ASTM standards shield people and businesses from the negative repercussions of defective products.

The three typical kinds of dimensional natural stone that ASTM addresses are as follows:

The three typical kinds of dimensional natural stone that ASTM addresses are as follows:

The material qualities, physical performance recommendations, and sampling pertinent to the selection of granite for general architectural and structural uses are all included in these standard standards for dimension stone.

The U.S. voluntary standards and conformity assessment system is managed and coordinated by the American National Standards Institute (ANSI), a private, non-profit organization. The Dynamic Coefficient of Friction test, which will be covered in more detail in a later section, is one of the ANSI tests that might be applicable to natural stone in addition to the usual ASTM tests mentioned below.

Why testing standards are so important?

Design teams may create project requirements that are clear and appropriate for the project by understanding physical property testing standards. A design team will be better equipped to choose a material and explain their decision if they are aware of how to apply the physical characteristics of natural stone to the application.

Very frequently, design teams produce generic, even conventional, natural stone requirements. This may be because they are unaware of the numerous tests and their objectives. If a design team chooses natural stone and is challenged with an alternative product, they may have to explain their decision if a generic-style specification is established. Specifications that are well-written offer the right direction, get rid of misunderstanding and exclude pointless needs.

Absorption and Bulk Specific Gravity Testing of Dimension Stone

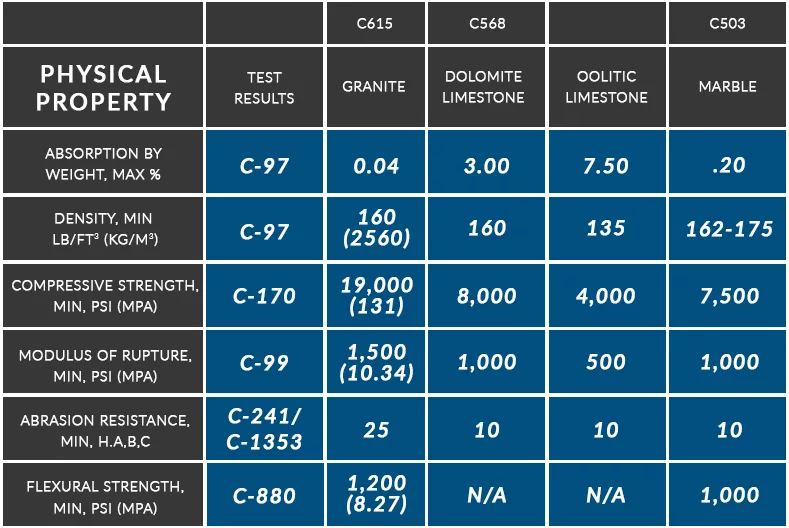

Two essential characteristics of natural stone are tested by ASTM C97: density, or how “heavy” the stone is, and absorption by weight. One of the most significant and popular ASTM tests is C97. Test specimens of the stone are dried for 48 hours in a ventilated oven before being weighed. The samples are then weighed again after spending 48 hours immersed in water. The difference between the dry weight and the wet saturated weight is the absorption value, which is given as a percentage.

Please take note that the stone’s absorption value is determined by its weight, not by its volume. Because one stone is denser than the other, two stones with the same volume may have different weights. The denser stone will have a lower absorption value than the lighter stone, assuming that both stones absorb the same quantity of water, as the volume of water absorbed will make up a smaller percentage of the total saturated weight. For natural stone, the Materials Standards additionally specify minimum densities.

The stone is suspended by a thin wire during the last stage of C97 testing, after which it is weighed. The stone’s specific gravity is calculated by weighing it against the unit weight of water. Testers can then determine a substance’s density thanks to its specific gravity, which is a crucial attribute to understand when, for instance, building support systems. The specific gravities of natural stones range from 2 to 3. In contrast to water, a stone has a specific gravity of 2.6, making it 2.6 times heavier.

The Importance of C97

In some applications, absorption may be a crucial factor, while it may not be at all. A stone with a low absorption rate is crucial to its long-term performance in this environment if the natural stone is meant for an application like outdoor pavement or the foundation course of a structure where it will be exposed to a lot of water, dirt, and salt in Northern latitudes. When used horizontally, the stone will absorb water that probably contains dirt and salt. As the water evaporates, the dirt and salt will be left behind. The stone can only hold so many solids before it begins to spell and decay over time. This is especially true in places where melting ice requires a lot of salt or other chemicals.

The stone’s absorption will also affect how it looks over time. Stones with high (like limestone) or low (like granite) absorption rates will both look well in arid conditions. While the look of the stone with the low absorption rate will preserve its original aesthetic for a much longer period of time after exposure to moisture, the stone with the greater absorption rate will seem mottled and black. If there is moisture behind the stone or in the substrate, this mottled pattern can even develop in dry weather.

The stone’s final purpose must also be taken into account. Is the stone going to be utilized inside or outside? Soft stones, like quartz, are perfect choices for indoor settings but do not hold up well outside where environmental demands are considerably higher.

Standard Test Methods for Abrasion Resistance of Stone Subjected to Foot Traffic

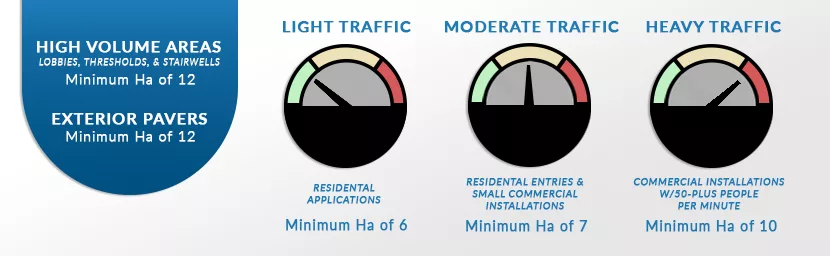

The potential for a stone’s resistance to wear brought on by foot activity is measured by ASTM C241 and ASTM 1353. These tests are designed to evaluate the potential strength and compatibility of stone materials for use in flooring, stairways, and other areas where foot traffic might cause abrasion. ASTM C241 is no longer commonly used and has mostly been supplanted by ASTM C1353, despite the fact that they are both utilized and approved in the market. The Abrasive Hardness value, or Ha, which represents a stone product’s resistance to abrasion, is assessed in both of these tests. The stone is more abrasion-resistant the higher the Ha number.

Standard Test Procedure for Dimension Stone Compressive Strength

A block of stone is pressed from both ends to gauge how much force is required for it to fail or crumble in order to measure a stone’s compressive strength. Compressive strength, one of the battery of tests, is no longer as significant for contemporary designs using natural stone than it previously was; in fact, it is frequently not applicable in paving applications.

Compressive strength is rarely necessary nowadays, unlike in the past when the design would have required for a stone to support other stone or other building parts structurally due to changes in building rules and attachment techniques. It’s important to remember that 19,000 psi is the minimum acceptable compressive strength and that carrying weight typically requires more than that.

While the criteria for the compression test are irrelevant to the specific application, when compressive strength is included in the battery of tests for natural stone, the stone may, regrettably, be rejected because it does not comply. There will be far fewer hoops to jump through and fewer blunders if you are aware of the various exams and their relevance.

Standard Test Procedure for Dimension Stone Rupture Modulus

The modulus of rupture test establishes the single-point breaking strength of stone. When attempting to assess the point-loading strength of stone, this test is most helpful. Or to put it another way, what is the stone’s breaking strength when pressure is applied to a very particular location of the stone? When examining the breaking strength at an anchor or load-bearing point, it might be useful. How would it affect the application, for instance, if a vehicle ran over a stone that was on the pavement surface? 1,500 pounds/psi is the bare minimum advised for a standard quality grade. Finally, thicker material can be required depending on the modulus of rupture.

Due to the fact that this test examines the stone in a limited region, results frequently outperform those of the closely related C880 – Flexural Strength test. It’s crucial to know which force, narrow point loading versus wider flexural pressure, to use when defining the proper test for a given application.

Standard Test For Flexural Strength of Dimension Stone

The test for flexural strength, which measures the breaking strength of stone over a span, maybe the most important one today (distance). The test assesses how much the entire span will stretch before it breaks rather than testing for fracture in a specific place. Using two places of loading and a sample that measures the exact thickness of the stone that will be placed, C880 assesses a stone’s bending strength. Flexural strength evaluates consistency throughout a wider range of motion. That is most likely the strength test that applies to both pavement and cladding applications today. The stone should have a minimum flexural strength of 1200 psi.

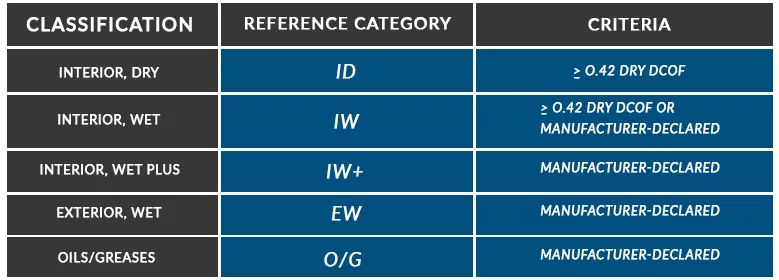

Dynamic Friction Coefficient

The slip resistance of stone finishes is a further test relevant to paving applications that were not previously mentioned within the ASTM testing. A Dynamic Coefficient of Friction test, which is covered by ANSI rules, is the test that is most frequently performed to assess if a certain stone color and finish combination is adequate for a particular application. ANSI A 137.1, a dynamic (testing many variables) co-efficient of friction test, was initially created by the Tile Council of North America and is intended to assess slide resistance for materials used in flooring or paving applications. According to comparison values provided by the test results, it may be determined whether the finish will eventually have more or less friction when it is wet.

The Conclusion

Use this example to illustrate the significance of ASTM values to a project’s success. A Northeastern project’s architect chose two stone hues for a challenging pavement style. Different colors were used since the project estimate was more expensive than anticipated. The alternative hues, albeit more reasonably priced, were three times more absorbent than the stone that was first requested. As the stone was set in position and installed, it quickly took on a look that was far different from what the architect or owner had envisioned.