Blog

The ABC of Granite Quality Grades for Granite Buyers

A large number of consumers don’t have any idea about the classification of different sorts of granite available in the competitive market. B2B buyers are well aware of the grades of granite and they purchase granite products as per their commercial needs. There are different levels of granite and each grade is quite different from one another in terms of quality. With this content, granite enthusiasts will know more about the aspects and features of granite stone that decide the level of granite quality.

Granite quality grades or levels accepted worldwide

Primarily, there are three grades or levels of granite quality. The grade of a granite slab or tile product is marked by a few features such as veins, colors, thickness, markings, pitting, and materials from which the stone is made of. When you compare a low-grade granite product with a higher grade product, you get visible differences. It is the presence of soft and hard materials in the stone that makes it resistant to the vagaries of nature. Let’s have a look at the top three granite quality grades that help granite enthusiasts understand the value of granite.

Commercial (Entry-level) quality granite

- “Builder” or “Commercial” grade

- Low-grade or second choice granite

- Excess soft minerals mixed into the stone

- Less color variation than higher-rated products

- The lowest grade of granite with standard colors

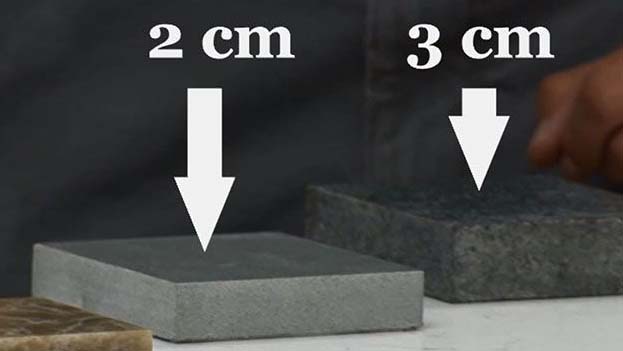

- Granite is cut thinner and is usually pre-fabricated

- Applications – Apartments, pre-fab remodels, and furniture

- General thickness size – 5/8 inch (15-16mm)

- Often imported from China

- Ideal for homeowners who want granite on a budget

- Not ideal for a high-traffic room

Standard (Level-2) quality granite stone

- Clear colors and interesting patterns

- Doesn’t deliver much uniqueness

- Tougher and durable than level 1 granite

- Little more unique in color and design

- Doesn’t have scarce unusual patterns and colors

- General thickness size – 3/4-inch

- More variety of marking on the surface

- Often imported from India or Brazil

Premium or top (Level-3) quality granite

- Exotic or high-end labels with a difference

- Top-quality with one-of-a-kind colors, variations & patterns.

- Very rare in appearance, colors, and pattern

- The most beautiful granite from a rare granite source

- Purchased by the United States from India or Brazil

- General thickness size – 3/4-inch

Reality check with inherent properties and laboratory tests

Granite is a natural stone and it has lots of inherent features that make the stone the first choice of all homeowners and construction engineers. To better understand the quality of granite stone, buyers must comprehend various properties of the stone. Besides, there are lots of laboratory tests that stone experts do to define the worth of the granite stone product.

Laboratory tests to decide the quality of granite stone

- Chemical resistance test

- Dimension test

- Frost resistance test

- Modulus rapture test

- Mohs scale hardness test

- Porosity test

- Specific gravity test

- Thermal shock test

- Water absorption test

Chemical properties of granite

- Alumina (Al2O3) – 11 14%

- Iron (Fe2O3) – 12%

- Iron (FeO) – 1 – 3%

- Lime – 1.00%

- Magnesia (Mg0) – .5 – 1%

- Potassium Oxide (P2O5) – 3 – 5%

- Silica (SiO2) – 7077%

- Soda (Na2O) – 3 – 5%

- Titina – Less than 1%(.38%)

- Water (H2O) – 0.03%

Physical properties of granite

- Porosity/permeability – Negligible (Range 0.2-4%)

- Thermal Stability (No changes with the change in temperature) – High resistance to chemical erosion and impervious to weathering from temperature

- Coefficient of expansion – 4.7×106inch – 9.0×106 inch

- Variegation – Consistency in color and texture

- Hardness – Hardest stone with excellent wear tendency

What is a quality inspection done by granite factories?

It is a granite stone factory where granite experts process various stone types to induce top quality stone products for various residential and construction projects. From stone cutting to stone polishing and from stone trimming to stone edging, there are lots of activities that granite experts do to bring the best out of the stone and make it useful for end-use. A certified granite stone supplier from India sells and supplies top quality granite colors at competitive prices. Although B2B granite buyers know everything about granite quality levels, yet following are some aspects that can help all granite buyers know more about how granite quality inspection is done at various stages at granite factories in India.

Activities to do in granite inspection

- Checking granite slab or tile size (standard or custom)

- Observing surface smoothness and finish

- Checking impurities inside the stone such as fissure, cracks, and speckles

- Checking granite uniformity and thickness variation

- Checking granite edges (should be properly trimmed)

- Check granite polishing with gloss meter (Ideal gloss more than 85)

- Checking the presence of lines and patches over the surface.

- The size of the granite (square or rectangular)

- Observing granite dimension as per actual size and tolerance

- Observing granite thickness (minimum 15 to 20 mm)

- Detecting Color and thickness uniformity

- Detecting Homogeneous crystalline texture

Some buyers also evaluate granite quality based on the cost and color of the granite stone products. While buying stone products from Indian, all buyers need to demand laboratory reports of granite stone of their choice.