Blog

Understanding The Indispensable Role of Packaging in Natural Stone Industry

Though the role of packaging is crucial in almost every industrial sector, it holds immense significance in the natural stone industry. From heavy weight to long-distance shipment, delicate finish, high-cost involvement, there are lots of reasons that put a heavy onus on the packaging part of natural stone exports. Let’s get to know more about this role in this blog post.

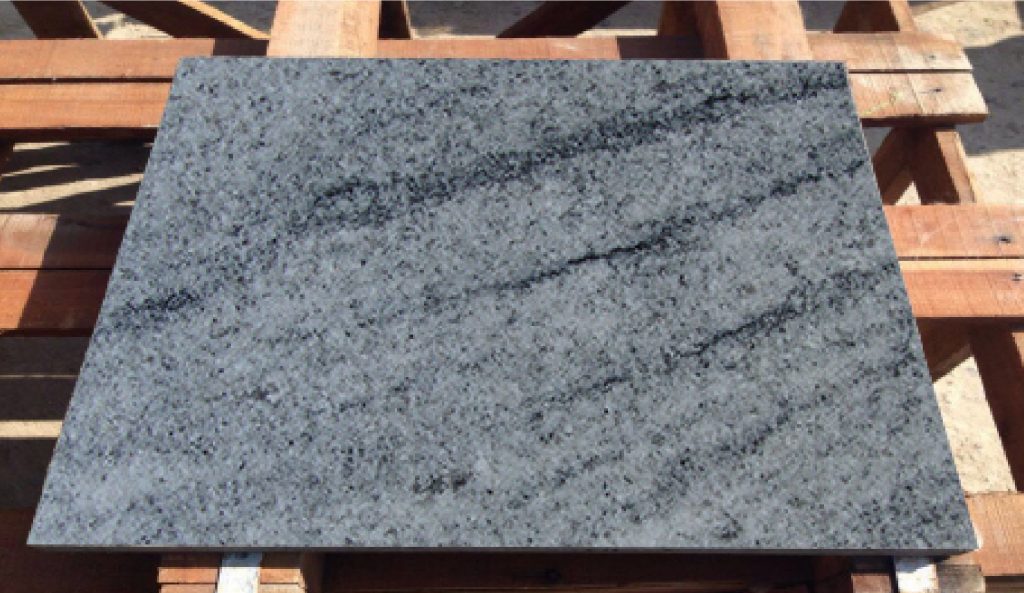

What is a natural stone?

In simple terms, a natural stone refers to a product that is extracted from the earth like granite, marble, sandstone, limestone, and others. These stones are formed over billions of years beneath the earth’s surface after getting exposed to intense heat and pressure.

What is the importance of packing natural stones?

Though these stones are quite hard and durable, they need to be dealt with care when it comes to using them in any construction project. This is because these stones can’t be used outright after getting extracted. They undergo various stages before becoming usable. For example, a specific finish is applied on their surface. Their edges are processed and they are cut to match the exact size of the application. This is a complex and costly affair and hence, it needs to be protected from adverse elements.

Let’s delve deeper to know more and understand how the right packaging benefits.

1. Avoid Physical Damage

Being very delicate, natural stones might break, crack, or get scratched while being transported. The stones are shielded from any potential physical impacts throughout their voyage by appropriate packaging, which acts as a protective barrier. It is necessary to cushion the stones and reduce any potential impact that shifting might have during handling and shipment by using sturdy boxes, padding materials, and other supports.

2. Abiding By International Regulations

Import laws, including packing specifications, vary depending on the destination nation. Breaking these rules may result in undeliverable shipments, additional expenses, or delays. Exporters need to be familiar with foreign packaging standards in order to make sure that the stones are appropriately packaged, labeled, and included with any required paperwork. In addition to speeding up the customs clearing procedure, compliance guarantees a trouble-free delivery experience, which increases customer satisfaction.

3. Reduce Vibrations

Natural stones are particularly vulnerable to the vibrations and shaking that occur frequently during international shipment. They may even loosen stones from their packaging or create tiny cracks. The stones will stay intact if precautions are taken to reduce vibration, such as cushioning the stones with foam, rubber, or other shock-absorbent materials. Further improving stability and reducing movement during transit can be accomplished by utilizing strategies like double-boxing or bracing.

4. Client Satisfaction

Providing natural stone products in immaculate condition promotes client satisfaction and protects the exporter’s reputation. The quality of materials received is highly valued by buyers of natural stone, and any damage sustained during transportation can negatively impact the reputation of suppliers or exporters. Deliveries that are safe and properly packaged show professionalism, care, and a dedication to providing an excellent product, which builds consumer trust and promotes repeat business.

5. Averts Moisture-related Damage

Natural stone items are susceptible to irreversible damage from water or moisture, which can cause discoloration, staining, or even deterioration. Moisture control must be taken into account during packing, and this can be achieved by using waterproof materials, desiccants, tight container closures, and, if necessary, moisture-resistant coatings. By taking these safety measures, you can be confident that the stones will always be in perfect condition and be available for use right away.

Different Types of Granite Packing

Countertops Packing

When packing granite countertops, professionals in granite packing prioritize using seaworthy and fresh wooden crates. For additional safety, they often use plastic coatings and cushioning materials like thermocol. To ensure that surfaces are never scratched during transit, thin plastic sheets are placed between two countertops.

Mosaic/Monument/Custom Products Packing

Granite products that are ready to use are placed straight into the wooden containers. Form or thermocol sheets are placed in wooden crates by granite packers prior to the packing process beginning. To protect polished surfaces, packers often choose to use thin polythene sheets. Additionally, to strengthen crates even further, iron or plastic straps work nicely around them.

The Conclusion

The role of proper packaging is essential in the natural stone industry. Being a high-valued item, granite needs special care and caution during transit. At Regatta Granites India, we conform to globally accepted packing standards to keep all our consignments safe & secure before they reach our buyers. We always resort to the use of high-quality packaging materials that result in faster and hassle-free delivery shipping of orders.